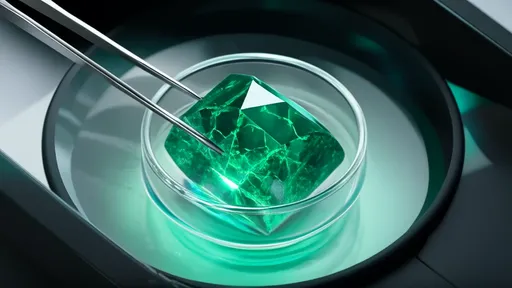

In the world of fine jewelry care, ultrasonic cleaners have long been regarded as a modern marvel, offering a swift and seemingly thorough method for restoring brilliance to precious stones. However, this technology, when applied without a deep understanding of gemology, can lead to catastrophic and irreversible damage. A particularly harrowing case study in this realm involves the ultrasonic cleaning of emeralds, a gemstone celebrated for its lush green hue but notoriously fragile internal structure. The core of the disaster lies in a single, critical phenomenon: the enlargement of pre-existing fractures, or inclusions, within the stone. This process, driven by the very mechanics of ultrasonic technology, transforms a routine cleaning into a destructive event, often leaving a once-valuable gem fractured and worthless.

The journey to destruction begins with the fundamental nature of the emerald itself. Unlike the pristine perfection of a diamond, an emerald is almost universally characterized by a unique internal landscape known as its jardin—the French word for garden. These are not flaws in the traditional sense but are instead accepted as part of the stone's character and identity. These inclusions can range from tiny, microscopic feathers to more significant fractures that reach the surface of the gem. Crucially, many of these fractures are traditionally filled with oils, resins, or polymers in a process called clarity enhancement. This treatment is standard practice in the industry; it stabilizes the stone and improves its visual appearance by reducing the visibility of the fractures. The filling material has a refractive index similar to that of the emerald, making the cracks less noticeable to the naked eye. However, this treatment creates a critical vulnerability. The bond between the natural beryl crystal of the emerald and the foreign filling material is inherently weak and susceptible to external forces.

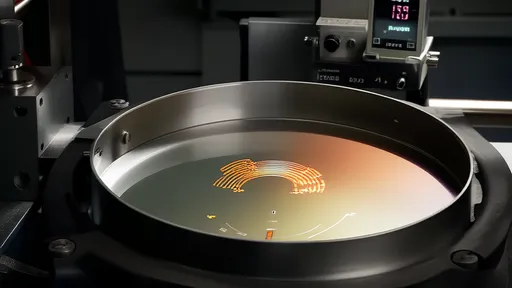

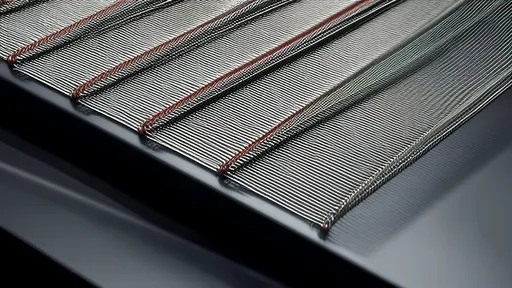

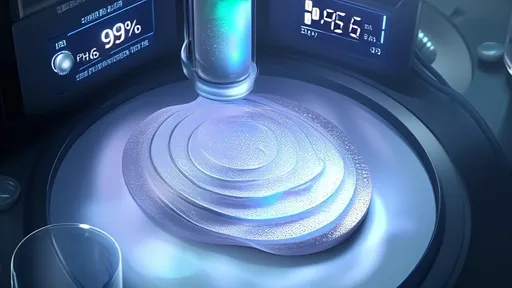

An ultrasonic cleaner operates on a simple yet powerful principle: it uses high-frequency sound waves, typically above the range of human hearing, to agitate a liquid cleaning solution. These sound waves create countless microscopic bubbles in the fluid through a process called cavitation. These bubbles form and collapse with immense energy, generating shockwaves and a powerful scrubbing action that dislodges dirt, grease, and grime from the surface of an object submerged in the tank. For a robust, non-porous item like a solid gold ring, this process is highly effective and safe. The metal can easily withstand the intense microscopic turbulence. For a complex, fractured, and treated structure like an emerald, it is akin to placing it in a miniature, violent earthquake.

The disaster unfolds in a specific and devastating sequence. First, the high-frequency vibrations transmitted through the liquid medium are directly transferred into the body of the emerald. Because the stone is a crystal, these vibrations travel through its lattice structure. When these vibrations encounter an internal boundary—such as the interface between the hard beryl and the softer, less dense filling material inside a fracture—they are reflected, refracted, and, most importantly, amplified. This concentrated energy begins to stress the already delicate junction. Second, and more critically, is the effect of cavitation. The collapsing bubbles near or, in a worst-case scenario, directly within a surface-reaching fracture exert tremendous localized pressure. This pressure acts as a wedge, forcefully prying at the walls of the inclusion. The filling material, never perfectly bonded to the emerald, is the first line of defense to fail. It can be literally shaken loose, dissolved by the cleaning solution, or vaporized by the heat generated from the cavitation process.

Once the protective filling is compromised, the naked fracture is exposed to the full, violent assault of the ultrasonic process. The shockwaves now attack the unprotected crack directly. The walls of the fracture, no longer supported by the filler, begin to vibrate independently at a microscopic level. This vibration, combined with the relentless prying action of the cavitation bubbles, causes the existing micro-fractures at the tip of the inclusion to propagate. In materials science, this is a classic example of fatigue failure, where a cyclic load—in this case, the millions of pressure cycles from the sound waves—causes a crack to grow. The initial, stable inclusion can rapidly enlarge, branching out into new, complex networks of fractures deep within the stone. Often, this damage is not immediately visible to the naked eye once the stone is removed from the cleaner and dried. The true extent of the catastrophe becomes apparent only later, as the new fractures alter the stone's light performance, creating a hazy, cloudy appearance known as a "sleepy" look, or worse, when a portion of the gem physically cleaves off.

The aftermath of such an event is financially and emotionally crushing. An emerald that may have held significant monetary and sentimental value is often permanently devalued, sometimes to a fraction of its original worth. Repair is frequently impossible; the internal damage is too extensive. The gem is, for all practical purposes, destroyed. This tragedy is almost entirely preventable. Professional jewelers and informed collectors are acutely aware of this vulnerability. The cardinal rule in emerald care is to avoid ultrasonic and steam cleaners altogether. Proper cleaning involves nothing more than a soft brush, mild soap, and lukewarm water, followed by a gentle pat-dry with a soft, lint-free cloth. This case stands as a stark and sobering reminder that advanced technology is not a substitute for specialized knowledge. Understanding the unique physical properties of precious materials is paramount, lest efficiency lead to irreparable loss.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025