In the ever-evolving landscape of additive manufacturing, the pursuit of aesthetic excellence has become as crucial as functional performance. While metal 3D printing excels at producing complex, high-strength components with remarkable precision, the as-printed surface often bears the tell-tale layered appearance and rough texture that betrays its automated origin. For applications where visual appeal, tactile quality, and a bespoke, artisanal feel are paramount—such as in high-end consumer products, architectural features, luxury goods, or custom automotive parts—achieving a hand-finished quality is not just a detail; it is the defining characteristic. This journey from a raw printed part to an object with soul and character involves a nuanced understanding of both traditional craftsmanship and modern post-processing techniques.

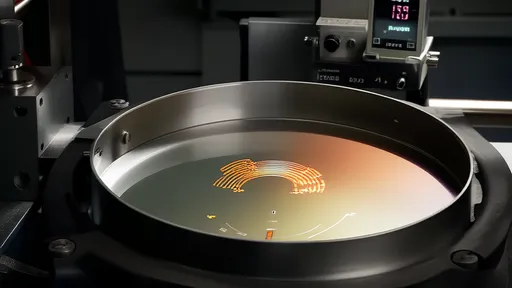

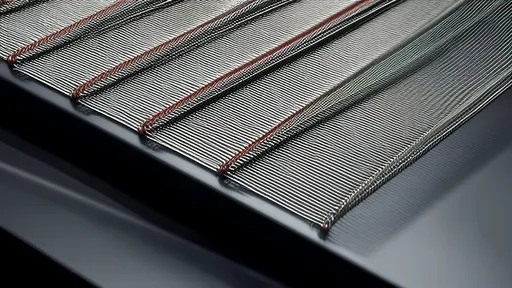

The initial state of a metal 3D printed part is a canvas of potential, but one that requires significant work. Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) processes typically leave behind a surface characterized by partially fused powder particles, layer lines, and a generally stochastic roughness. This surface, while excellent for certain engineering functions like adhesion for thermal sprays or coatings, is far from the smooth, refined, or intentionally textured finish associated with hand-worked metal. The first step in the post-processing chain almost always involves the removal of this loose and partially sintered powder and the support structures that were essential during the build. Techniques like abrasive blasting, often with fine glass beads or aluminum oxide, are employed not to smooth the surface per se, but to clean it and create a uniform, matte baseline texture. This is the foundational preparation, the blank slate upon which the artisanal qualities will be built.

To truly begin mimicking the nuances of handcraftsmanship, one must move beyond automated uniformity and introduce processes that impart unique, variable characteristics. This is where the marriage of machine and human skill becomes critical. Mechanical finishing methods like grinding, polishing, and tumbling can achieve a high gloss, but a mirror finish can often feel cold and industrial, lacking the warmth of a hand-polished piece. The key to a handcrafted texture lies in introducing controlled imperfection and depth. Skilled technicians using handheld tools—angle grinders with various flap discs, polishing wheels with compound, or even manual sanding with progressively finer grits—can apply varying pressures and motions. This human touch creates subtle variations in the surface reflectivity and texture that a fully automated robotic polishing cell, programmed for perfect consistency, would intentionally avoid. The result is a luster that has depth and life, catching the light in a way that feels organic and personal.

For a more pronounced and intentional textured finish, techniques borrowed from jewelry making and traditional metalworking come to the fore. Processes like hand-brushing or linishing create distinctive directional satin finishes. The craftsman's skill determines the consistency and length of the strokes, embedding a unique signature into the metal. Similarly, hammering or peening the surface with specialized hand tools can create a dimpled or stippled texture that is deeply reminiscent of blacksmithing. While these textures can be simulated through chemical or automated means, the human-controlled process introduces a randomness and variation that is incredibly difficult to replicate algorithmically. Each hammer strike is slightly different, creating a dynamic surface that tells a story of its creation.

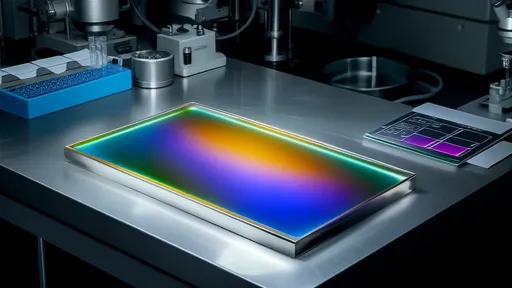

Chemical post-processing offers another avenue for achieving unique aesthetic qualities. Electropolishing, for instance, uniformly removes a microscopic layer of material, smoothing peaks and valleys to create a clean, deburred surface with a bright, satin-like sheen. While highly controlled, the specific current, temperature, and bath composition can be tuned to achieve slightly different results, allowing for a degree of customization. A more artistic application involves patination, a chemical process that alters the color of the metal surface. By applying specific compounds to heated or untreated metal, craftspeople can induce a wide spectrum of colors—deep blues, vibrant greens, rich browns, and fiery oranges—that are unique to copper, bronze, and certain stainless steels. This aging process, often associated with classical sculpture, adds a layer of history and depth that is profoundly artisanal. The control of the reaction through heat, application technique, and subsequent sealing is a deeply skilled craft in itself.

Perhaps the most advanced fusion of technology and craftsmanship lies in hybrid finishing approaches. Here, the part may undergo an initial automated smoothing process, such as mass finishing or fluidized bed grinding, to efficiently remove the majority of the surface roughness and achieve a consistent baseline. This is followed by targeted, manual finishing operations. A technician might then use a micro-abrasive blaster (a smaller, hand-held version of a sandblaster) to selectively texture specific areas, highlight contours, or even engrave fine details. This combination allows for economic efficiency on simple surfaces while reserving costly manual labor for the critical areas where aesthetic value is added. It acknowledges the strengths of both machine consistency and human artistry, using automation to set the stage for the craftsman to perform.

The final step in bestowing a hand-finished quality is often the application of a protective yet enhancing coating. While a simple clear coat will preserve the surface, a skilled application of wax or oil—rubbed in by hand, buffed to a soft glow, and often built up in layers—can profoundly deepen the color and sheen of the underlying metal. This process, much like finishing fine wooden furniture, relies on the warmth and pressure of human hands to work the material into the surface, creating a patina that feels cared for and cherished rather than simply coated.

In conclusion, transforming a metal 3D printed part from a marvel of modern engineering into an object with handcrafted texture is a deliberate and often intricate dance between technology and traditional artisanal skill. It requires moving beyond the pursuit of perfect uniformity and embracing the subtle variations, controlled imperfections, and deep, complex textures that only human hands and expert eyes can provide. It is not merely a process of smoothing and polishing, but one of character implantation. By thoughtfully sequencing automated cleaning, skilled manual finishing, artistic chemical treatments, and protective hand-applied coatings, manufacturers can create metal objects that possess not only the structural integrity of additive manufacturing but also the soul, story, and irresistible tactile appeal of a handcrafted masterpiece. The future of high-end additive manufacturing lies in this synergy, where the machine creates the form, and the human hand breathes life into it.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025