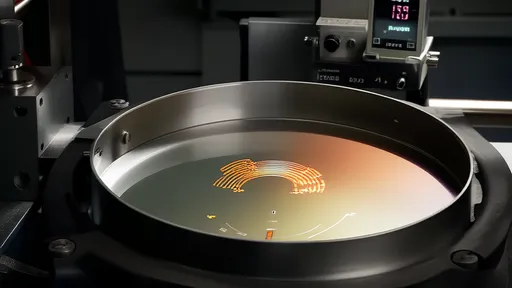

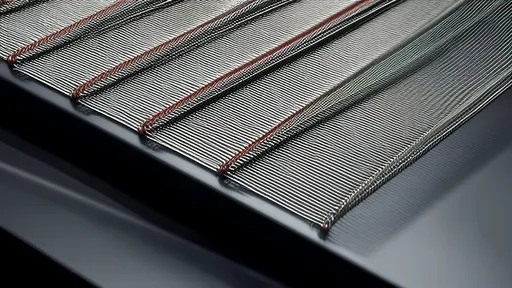

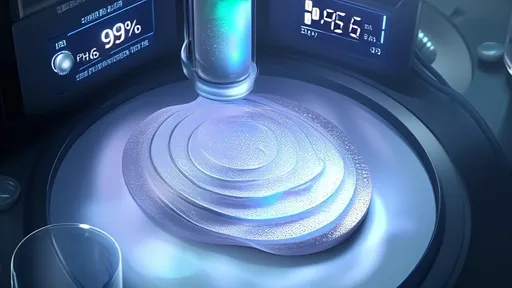

In the world of jewelry care, ultrasonic cleaners have become a popular tool for both professionals and enthusiasts seeking efficient and thorough cleaning results. These devices utilize high-frequency sound waves to create microscopic bubbles in a cleaning solution, which then implode and dislodge dirt, oils, and other contaminants from the surface and crevices of gemstones and jewelry settings. However, the safety of using ultrasonic cleaners on various types of gemstones has long been a topic of debate, largely due to the different frequencies employed by these machines and the diverse physical properties of gem materials.

Ultrasonic cleaners typically operate within a frequency range of 20 kHz to 50 kHz, with some specialized units reaching up to 100 kHz or higher. The frequency determines the size and energy of the cavitation bubbles: lower frequencies produce larger, more energetic bubbles that are effective for heavy cleaning but may pose risks to delicate gems, while higher frequencies generate smaller, gentler bubbles suitable for more fragile materials. Understanding how these frequencies interact with different gemstones is crucial for preventing damage such as cracking, fracturing, or surface pitting.

Diamonds, rubies, and sapphires are among the most durable gemstones and can generally withstand ultrasonic cleaning at standard frequencies. These stones rank high on the Mohs scale of hardness and have no inherent cleavage planes, making them resistant to the mechanical stress caused by cavitation. However, even with these robust gems, caution is advised if they have inclusions or fractures that could be exacerbated by the vibrations. Additionally, jewelry settings should be inspected for looseness, as the ultrasonic process can potentially dislodge stones that are not securely set.

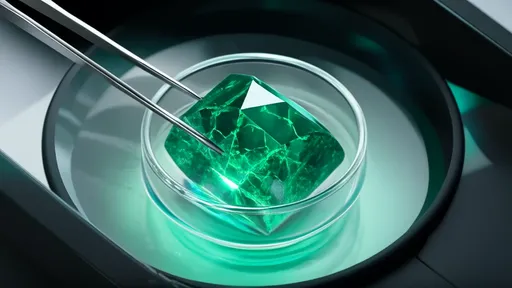

Emeralds present a more complex case due to their common treatments and natural characteristics. Most emeralds are treated with oils or resins to fill surface-reaching fractures and improve clarity. Ultrasonic cleaning, especially at higher frequencies or with prolonged exposure, can remove these fillers, leading to a dull appearance or increased visibility of inclusions. Moreover, emeralds are relatively brittle and prone to chipping, so many jewelers recommend avoiding ultrasonic cleaners altogether for these stones, opting instead for gentle hand cleaning with mild soap and water.

Softer gemstones such as opals, pearls, and turquoise are highly susceptible to damage from ultrasonic cleaning. Opals contain water within their structure, and the heat generated by ultrasonic cleaners can cause them to crack or lose their play-of-color. Pearls are organic materials with delicate nacre surfaces that can be eroded or scratched by the cavitation process. Turquoise is often porous and may be treated with wax or plastic; ultrasonic cleaning can strip these enhancements and lead to discoloration or structural weakness. For these materials, alternative cleaning methods are strongly recommended.

Gemstones with distinct optical properties or unique internal features require special consideration. For example, tanzanite has pronounced cleavage, meaning it can split along certain planes if subjected to vibration or sudden temperature changes. Ultrasonic cleaning poses a significant risk for such stones. Similarly, lab-created gems like cubic zirconia or moissanite, while hard, may have different thermal expansion properties than natural stones and could be damaged by the heat generated during ultrasonic cleaning. It is always prudent to research the specific vulnerabilities of each gem type before proceeding.

The cleaning solution used in conjunction with ultrasonic frequency also plays a critical role in safety. Some solutions contain ammonia or other chemicals that can harm certain gems. For instance, ammonia can damage the surface of pearls and corrode the metals in settings. Always use a solution recommended for jewelry cleaning and avoid harsh chemicals. The temperature of the solution should be monitored, as excessive heat can thermal shock gems, particularly those with inclusions or fractures.

Professional jewelers often perform tests on unknown or sensitive stones before subjecting them to ultrasonic cleaning. This may involve using a lower frequency setting for a short duration and inspecting the gem under magnification for any signs of damage. For valuable or antique jewelry, consulting a certified gemologist or jeweler is advisable to determine the safest cleaning method. Ultrasonic cleaners are powerful tools, but their misuse can lead to irreversible damage, underscoring the need for education and caution.

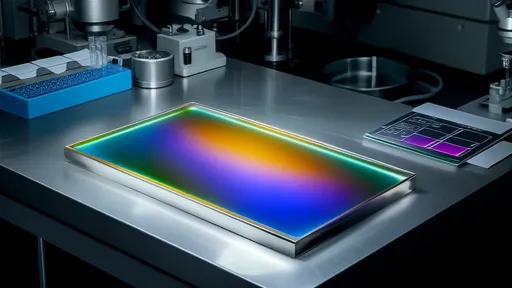

In recent years, advancements in ultrasonic technology have led to the development of multi-frequency cleaners that allow users to select settings tailored to specific gem types. These devices offer greater control and safety, enabling effective cleaning without compromising the integrity of delicate stones. However, even with these innovations, the fundamental principles of gemstone care remain: know your materials, start with the gentlest method possible, and when in doubt, seek professional advice.

Ultimately, the relationship between ultrasonic frequency and gemstone safety is nuanced, dependent on a stone's hardness, structure, treatments, and existing flaws. While ultrasonic cleaners can restore brilliance and remove stubborn grime, they are not universally suitable for all jewelry. A thoughtful approach, combining knowledge of gemology with an understanding of ultrasonic technology, ensures that these devices are used effectively and safely, preserving the beauty and value of precious gemstones for years to come.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025