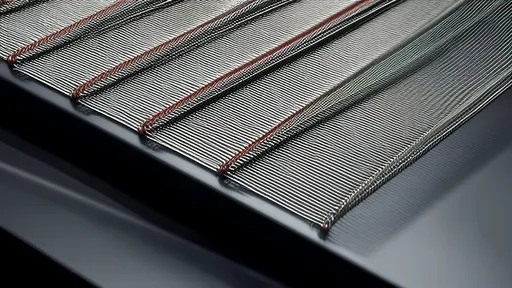

Titanium has long captivated engineers and designers with its paradoxical nature—a metal boasting the strength of steel at nearly half the weight. Yet beyond its mechanical prowess lies an aesthetic dimension that has remained underexplored until recent years. The emergence of anodic oxidation as a surface treatment technique has unlocked a vibrant palette of colors on titanium, transforming it from a purely functional material into a medium for artistic and commercial expression. This technological advancement is not merely about adding hue; it represents a sophisticated interplay between science, art, and industry that demands systematic documentation and standardization.

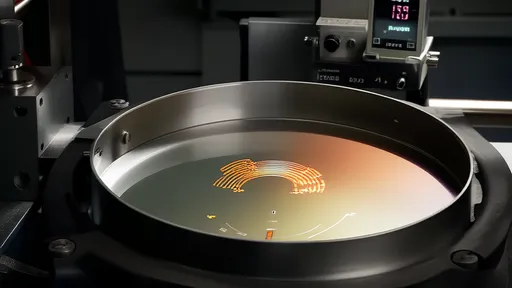

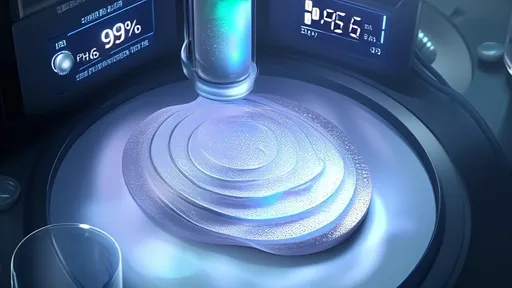

The process of anodic oxidation, while complex in its electrochemical details, essentially involves immersing titanium in an electrolyte solution and applying a controlled voltage. This treatment forms a thin oxide layer on the metal's surface whose thickness determines the color through light interference phenomena—similar to how oil slicks display rainbow patterns or butterfly wings shimmer with iridescence. What makes this process particularly fascinating is its precision: variations of mere nanometers in oxide thickness can produce entirely different colors, making the technique both powerful and delicate. This sensitivity to parameters means that reproducing specific shades consistently requires exact control over numerous variables including voltage, electrolyte composition, temperature, and processing time.

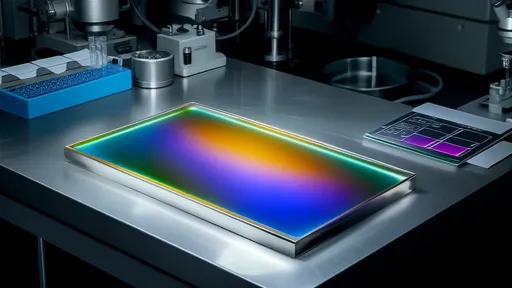

Recognizing the growing industrial and artistic applications of colored titanium, researchers and industry leaders have initiated efforts to create comprehensive color databases for anodized titanium. These databases aim to catalog the relationships between processing parameters and resulting colors, serving as essential references for manufacturers, designers, and artists working with the material. Unlike simple color charts, these databases incorporate multidimensional data that captures the complex interdependencies between various anodizing conditions and their visual outcomes. Such resources are becoming increasingly valuable as colored titanium finds applications in diverse fields from aerospace components and medical implants to jewelry and architectural elements.

The construction of these color databases represents a significant scientific undertaking that combines materials science with color theory. Researchers must systematically anodize titanium samples under carefully controlled conditions, measuring both the processing parameters and the resulting optical properties. Advanced spectroscopic analysis characterizes the colors not merely as RGB values but in terms of their spectral characteristics, accounting for how they appear under different lighting conditions—a crucial consideration for practical applications. This data-intensive approach ensures that the databases capture the full complexity of anodized titanium's visual properties, including its characteristic metallic shine and color-shifting tendencies when viewed from different angles.

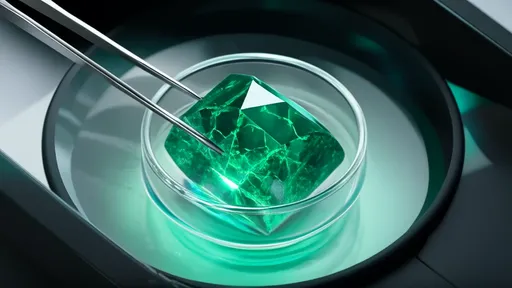

Beyond mere cataloging, these databases enable predictive modeling of anodizing outcomes. By applying machine learning algorithms to the accumulated data, researchers are developing systems that can recommend specific anodizing parameters to achieve desired colors with minimal trial and error. This capability is particularly valuable for industrial applications where color consistency across production runs is essential. The predictive models account for subtle interactions between variables that might not be intuitively obvious, allowing for optimization of the anodizing process for both color quality and production efficiency. These computational tools represent a significant advancement over traditional empirical approaches that relied heavily on artisan-like experience and experimentation.

The implications of these color databases extend beyond technical applications into the realms of design and sustainability. Designers working with titanium can now explore color possibilities virtually before committing to physical prototypes, reducing material waste and accelerating creative processes. The ability to precisely reproduce colors also supports circular economy principles by facilitating repairs and replacements that match original components perfectly. Furthermore, as anodic oxidation is an environmentally friendly process that doesn't involve paints or dyes—the colors are structural rather than pigment-based—it aligns with growing demands for sustainable manufacturing practices. The databases thus support not just aesthetic and functional goals but environmental responsibility as well.

Looking forward, the development of titanium anodizing color databases continues to evolve with technological advancements. Researchers are exploring how different titanium alloys and surface preparations affect color outcomes, expanding the databases to cover more material variations. There is also work underway to standardize measurement and characterization methods across different laboratories and industries, ensuring that color data remains consistent and comparable regardless of its source. As augmented reality and digital design tools become more sophisticated, these databases may integrate directly into design software, allowing real-time visualization of how anodized titanium components will appear in their intended environments. This integration promises to further blur the boundaries between material science, digital technology, and creative expression.

The marriage of titanium's lightweight strength with the vibrant colors made possible through anodic oxidation represents a remarkable convergence of material science and aesthetic possibility. The systematic construction of color databases for this process does more than just document technical relationships—it creates a common language through which engineers, designers, and artists can explore and exploit titanium's full potential. As these resources grow in comprehensiveness and sophistication, they will undoubtedly unlock new applications and innovations that we can scarcely imagine today, continuing titanium's transformation from a merely functional material to a medium of both engineering excellence and artistic expression.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025